110/6 kV Substation Design and Construction (EPC) for a Cardboard & Paper Factory

About the project

Challenge

Location: Ukraine

Client: NDA

Status: Completed

Services Wind

Power Substations and Transmission Lines: Design, Construction, and Maintenance

Services provided

Voltage Group delivered full-cycle EPC (Engineering, Procurement, and Construction) services, covering:

1. Technical and Engineering Design:

Development of the full set of project documentation for the 110/6 kV transformer substation.

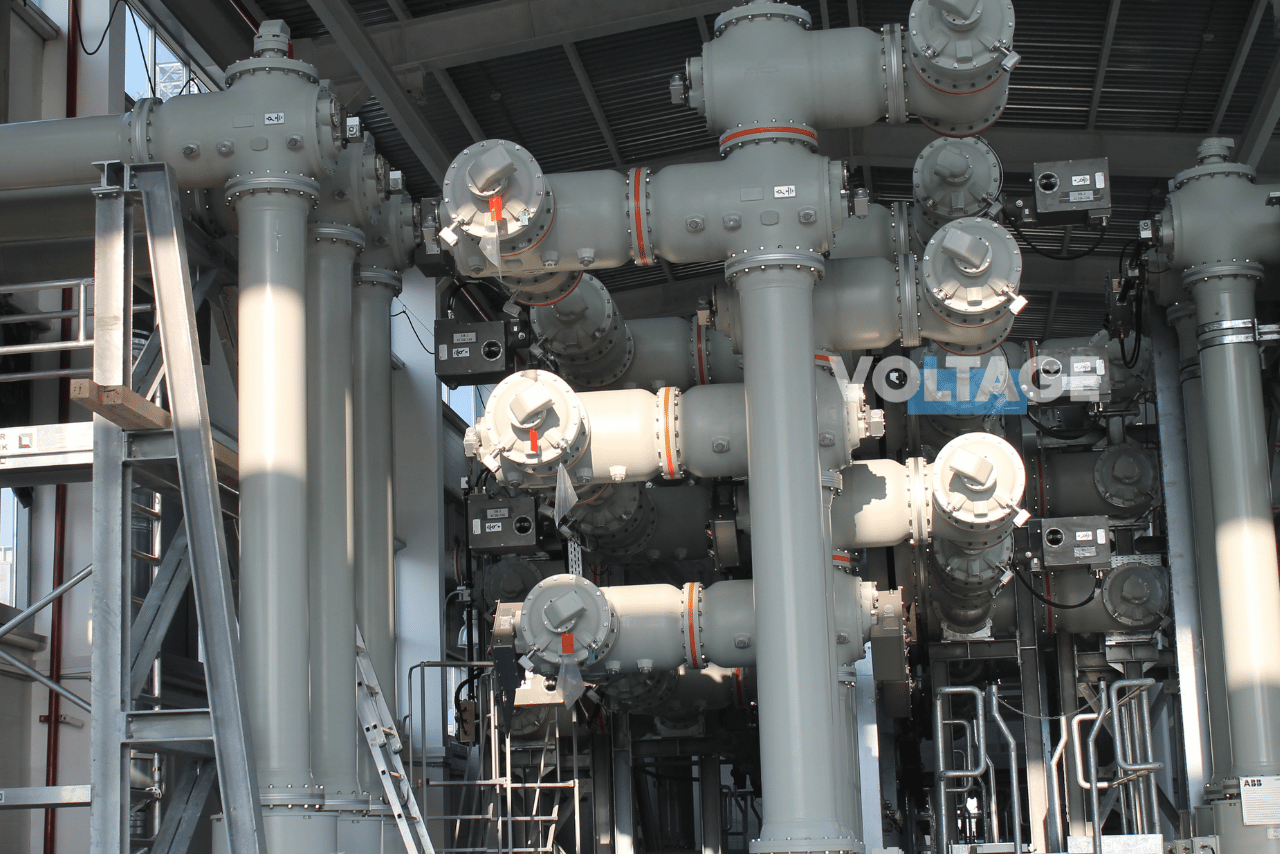

Design of 110 kV switchgear (VRP-110) using an H5 single-line diagram.

Selection and configuration of 110 kV switchgear components and 110/6 kV power transformers.

2. Medium Voltage Systems and Equipment:

Design and integration of the 6 kV switchgear (RP-6) system for internal plant distribution.

Relay protection systems for both 10 kV and 6 kV networks.

3. Structural and Architectural Engineering:

Architectural and structural design of substation buildings, foundations, and support infrastructure.

Engineering of both concrete and steel structures to support electrical equipment and cable lines.

4. Automation and Metering Systems:

Deployment of telemetry and automation systems for real-time monitoring and control.

Design and integration of electricity metering systems for commercial and operational use.

5. Cable Line Design and Routing:

Engineering solutions for 110 kV and 6 kV cable line installations, including cable trenching and routing.

Outcome

The result was a modern, high-performance 110/6 kV transformer substation that fully meets the energy needs of the production facility—both current and projected. All works were delivered on time, on budget, and to a high technical standard, with full alignment to Ukrainian energy regulations and safety protocols.

The client praised Voltage Group for its:

Strong technical competence and engineering depth.

Proactive handling of operational matters.

Transparent communication and financial integrity throughout the project lifecycle.

This project demonstrates Voltage Group’s ability to provide end-to-end high-voltage substation solutions for industrial manufacturing clients—ensuring safe, efficient, and expandable energy infrastructure.