110/10 kV Substation Design and Construction for a Dairy Production Facility – Industrial Power Infrastructure Project in Ukraine

About the project

Challenge

Location: Ukraine

Client: NDA

Status: Completed

Services Provided

Power Substations and Transmission Lines: Design, Construction, and Maintenance

Services provided

Voltage Group provided full-cycle EPC (Engineering, Procurement, and Construction) services tailored for high-voltage infrastructure in the manufacturing sector:

1. Electrical Engineering and Substation Design:

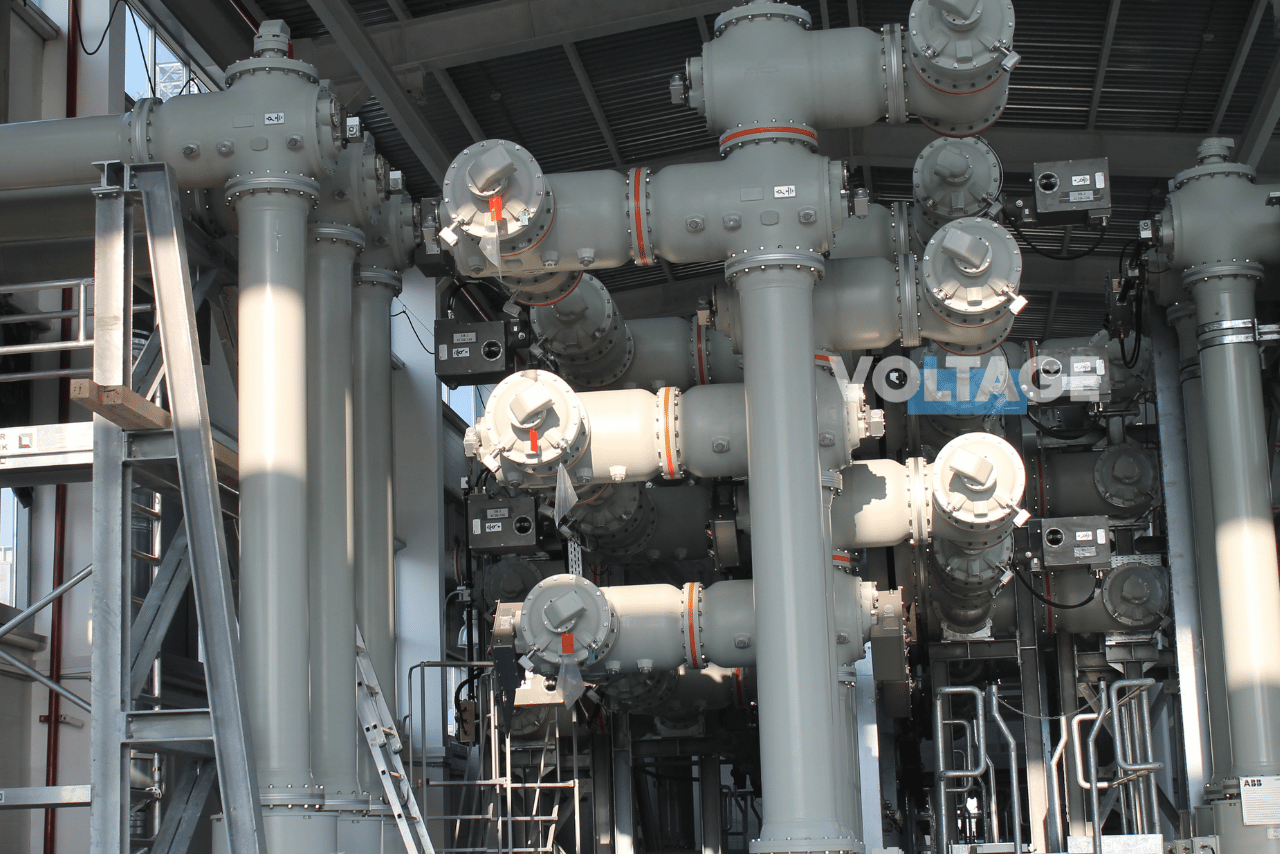

- Development of electrical schemes and H5 substation layout using ABB equipment.

- Design of 110 kV switchgear with sectional disconnectors, current transformers, and circuit breakers.

2. High-Voltage Equipment Implementation:

- Installation of two 110/10 kV power transformers.

- Configuration of 110 kV breakers, surge arresters, sectional busbars, disconnectors, and oil collection systems.

- Integration of remote metering and maintenance bypasses for optimal performance and flexibility.

3. Medium-Voltage Switchgear (10 kV):

- Design and installation of RU-10 kV switchgear based on a standardized “10-1” scheme.

- Transformers of own needs (10/0.4 kV), voltage transformers, LV switchboards, and DC cabinets.

4. Civil and Structural Engineering:

- Construction of all buildings, foundations, and auxiliary facilities required for the substation.

5. Relay Protection and Automation Systems:

- Engineering and setup of relay protection, automatic control logic, and fail-safes.

6. SCADA and Telemetry Systems:

- Deployment of telemetry, remote control, and monitoring systems for safe and efficient operations.

7. Commercial Electricity Metering:

- Installation of a fully integrated commercial energy metering system aligned with regulatory standards.

Outcome

The project resulted in a fully functional and technically robust 110/10 kV substation, enabling stable, high-capacity electricity supply for a large-scale manufacturing facility. The solution not only improved power quality and reliability but also laid the foundation for future expansion.

Voltage Group demonstrated its ability to deliver critical energy infrastructure for the agri-industrial sector, coordinating all work with minimal impact on production. The client recognized the company’s engineering expertise, disciplined execution, and high standards of safety and communication.

Voltage Group continues to serve as a reliable EPC contractor for industrial substations and energy infrastructure across Ukraine and other European markets.